- Skin Gelatine Production Line

- Bone Degreasing Production Line

- Home

- Products

- Skin Gelatine Production Line

- Bone Degreasing Production Line

Gelatine Process Solutions And Technology For You

International Professional Gelatine Process Solutions And Optimzied Equipment Supplier

HOT PRODUCTS

Gelatine Extraction Vessel Gelatine Extractor

Gelatine Dryer Continuous Band Dryer For Gelatine Drying

Gelatine Votator Scraped Surface Heat Exchanger for Gelatine Extruding Gelatine Gelling Equipment

Skin Gelatine Production Line

Product Gallery

gelatin production equipmentGelatin Equipment

GEL MACHINE provides full range of gelatine processing equipment for skin gelatine production line, bone gelatine production, fish gelatine production line, and hydrolysed collagen production line.

ABOUT THE COMPANY

For Gelatine Processing Technology

Gelatine is made of native collagenous raw materials which are derived from the connective tissues from animals, such as bones, skin and fish scale. For skin raw material, the most widely used raw materials are pig skin and hide split. The skin gelatine manufacturing process makes the collagen soluble in hot water. The incoming raw material is first washed with water and pretreated with acid or alkali. The pretreatment may be a short time soaked in a dilute acid solution or a prolonged soak in a saturated lime solution. Gelatine derived from acid-cured tissue is known as Type A Gelatine. Gelatin derived from alkali-cured tissue is known as Type B Gelatine.

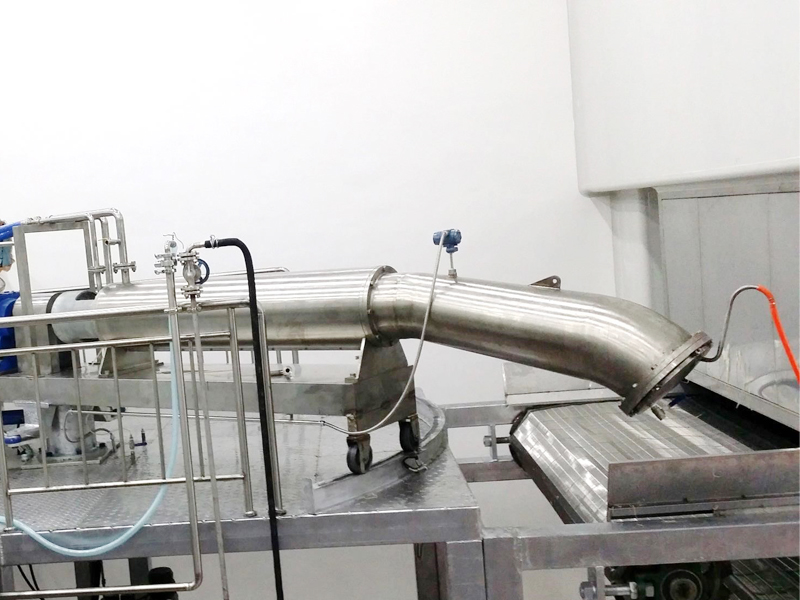

After the sterilization process, the gelatine solution is chilled using a scraped surface heat changer, called”votator”, “gelatine extruder” and “chemetator” by different manufacturers as well.

GEL MACHINE

Gelmachine is a leading global provider of first-rate products in the areas of gelatine processing equipment, beverage equipment and fluid handling. With these as its base, Gelmachine aims to help enhance the productivity and competitiveness of its customers in various industries throughout the world. We define their challenges and deliver sustainable products and solutions that meet their requirements – mainly in food, pharmaceutical and beverage industries.

We define our purpose as accelerating success for our customers, people and planet. As we are dedicated to outstanding customer service, an inspiring and embracing workplace, and with sustainability in our genetic code.